LCA in short

Life Cycle Assessment (or LCA) is THE essential method for understanding the environmental impact of a product or service. But why carry out an LCA? How do you go about it, and what tools should you use? What is the quality of this method? What stage should the synthesis take? Inovacomm explains it all!

LCA stands for Life Cycle Assessment. To give a clear definition, LCA is an evaluation method that quantifies the environmental impacts of a service or product throughout its life cycle. According to ADEME, this method is currently the most advanced and scientifically robust in terms of eco-design and environmental performance.

Incidentally, the first life-cycle analyses were carried out in the USA in the 1960s. In fact, the first LCA study and method was carried out by Coca-Cola!

The phases of a product's life cycle

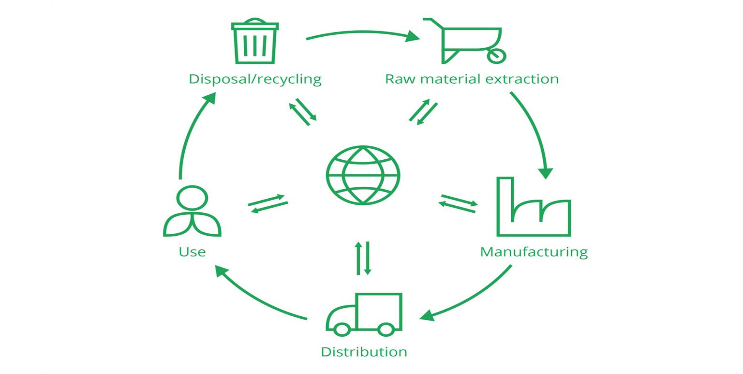

The life cycle of a product is made up of 5 phases:

- Raw materials: extraction, processing, supply, etc.

- Manufacture of the finished product: assembly, packaging, construction, etc.

- Product release: transport, distribution and marketing

- Product use: unpacking, use, maintenance, etc.

- End-of-life: collection, transport, recycling, waste treatment, etc.

One of the reasons why LCA is such a robust environmental assessment is its dual approach, which combines the “pure” life cycle of the product/service with consideration of all the flows involved in its manufacture.

- The “life cycle” approach

This first approach means that all the stages of a product's lifecycle, as described above, are taken into account in the study and synthesis, in order to identify the flows.

- The “multi-criteria” approach

The multi-criteria approach refers directly to this notion of flows. It covers everything that goes into making the product, and everything that comes out. We speak of input flows (water resources, oil, gas,

etc.) and output flows (gaseous emissions, liquid waste, etc.). Carrying out an LCA therefore involves collecting information on flows and quantifying them during the assessment.

The Purpose of an LCA

A life cycle analysis (LCA) serves to make more informed decisions about the entire manufacturing process of a product. The results help visualize the most polluting stages of a product's life cycle, allowing for improvements to reduce its environmental impact and make it more sustainable.

It’s similar to the principle of a carbon footprint assessment. Conducting a carbon footprint assessment for a company is the first step in studying and reducing its emissions. It acts as a tool for diagnosis, evaluation, summary, and self-assessment before taking action.

An LCA can also be used to compare different options to determine the best one. For example, in distribution, it can help understand the environmental impacts of various transportation options and compare them. Potential scenarios are constructed to eliminate those with fewer benefits, thereby protecting the environment and promoting eco-design. The same approach can be applied to materials, production techniques, or packaging.

Reducing the Environmental Impact of Our Products

Once a "diagnosis" of the product is obtained, its environmental and carbon impacts are known, enabling actions to reduce them. This effort to design products that adhere to sustainable development and environmental principles is known as eco-design.

For example, in the case of a pen, raw materials have significant environmental impacts compared to its use and distribution. To design a more sustainable pen, the focus should be on the extraction of the raw materials needed for its manufacture or construction. The questions to ask: Is it more beneficial in terms of environmental and carbon impact to switch to a different material? Should we change the supplier of raw materials? In short, make a current assessment and almost give it a grade to determine the direction to take.

Any organization offering goods or services can engage in life cycle analysis. Of course, it requires the necessary knowledge, which often involves training in the LCA method. Implementing solutions requires the use and mastery of tools, specific reasoning, specialized databases, etc. Even before conducting the various impact calculations, data collection (activity factors and emission factors) is the most time-consuming and requires meticulous classification.

At Inovacomm, we took on the challenge of conducting LCAs since 2023. Camille, our Head of CSR, is responsible for data collection and calculation tables, although the approach is team-wide. Indeed, everyone is involved and/or made aware of these sustainability challenges, from designers to the head of procurement, to the sales team, with a constant aim to improve. It’s about thinking ahead, from the very first steps of a project, to design products in the cleanest and smartest way possible for our customers.

For detailed results, click here (LCA file to download).