Aluminium

Aluminium does not exist naturally. It is extracted from an ore called bauxite, which is ground and then mixed with sodium hydroxide. This mixture is allowed to settle before being chemically separated, at which point only the aluminium oxide will be kept and then heated to a high temperature (1,300°C). This material then becomes aluminium due to electrolysis.

Aluminium is the most commonly used metal after iron. It can be found in transport (planes, train wagons, cars), the electrical industry, construction (windows, doors, verandas) and ornamental architecture, household utensils (pots, cutlery) and in packaging (cans, aluminium paper, trays).

It is also used in many alloys with various properties.

Pros

Aluminium naturally generates an oxide layer that protects it from corrosion. Different types of surface treatment can further improve this resistance (anodising, lacquering, etc.). Its resistance to corrosion makes it significantly easier to maintain without using chemical products.

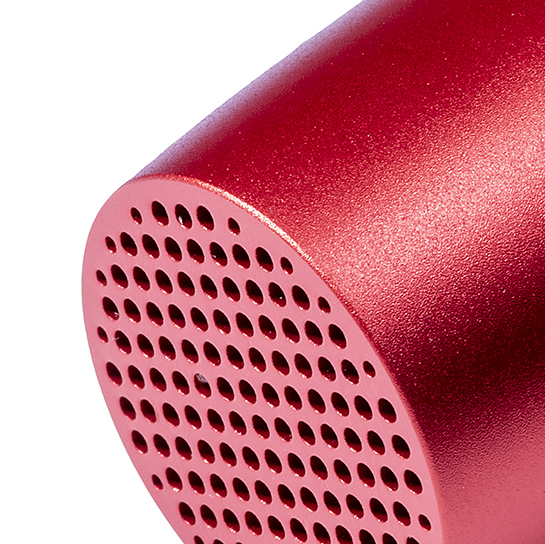

In terms of finishes, aluminium is incredibly versatile, as it comes in a multitude of colours, shades and textures. It can even imitate other materials. It is also very light and malleable which makes it perfect for moulding and thermoforming. Aluminium is as strong as steel and has great longevity.

Aluminium is 100% recyclable without damaging its properties. Recycling it requires little energy, at only 5% of the energy used to produce the initial metal.

Cons

Aluminium is harder to shape than steel or stainless steel. It is also fragile in the event of shocks; to limit possible impact marks, the aluminium used must be thick or turned into a more resistant alloy.

Aluminium easily conducts both heat and electricity, which should be taken into account when you design your product.

We would be happy to produce your next aluminium item. Please do not hesitate to contact us to discuss your future project.