Biocomposites

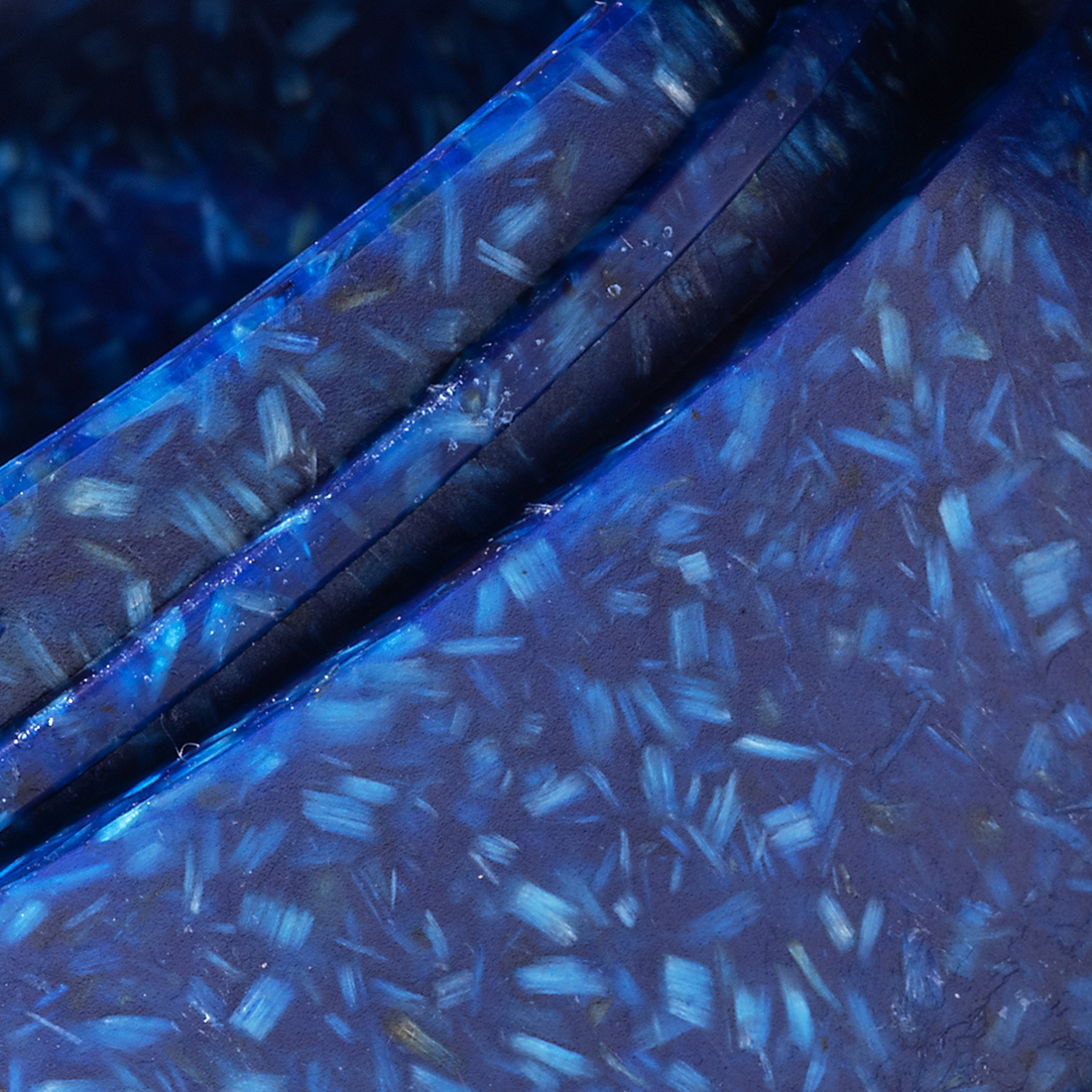

A composite material is a combination of at least two components with properties that complement each other. This new combined material has extra properties that the individual components did not have. A “biosourced composite” or “biocomposite” generally refers to the use of plant fibres added to plastic matrices made from petroleum or biological sources.

The fibres used fall into two main categories: synthetic fibres (carbon, glass, basalt, etc.) and natural fibres, either from plants (wood, flax, hemp, sisal, etc.) or animals (silk, wool, hair, etc.). The plant fibres can come from wood, stems (linen, jute, hemp), leaves (sisal, pineapple, banana, palm), fruit (cotton, coconut) or grass (bamboo, rice). The most widely used fibres are wood, flax and hemp fibres.

In terms of the matrices, in addition to common petrochemical plastics such as PE, PP and PVC, an increasing amount of biopolymers are being used, such as bio-PE (sugar cane), PLA (corn starch, beetroot or sugar cane), PHA (potato) or PBS (plant waste). The biocomposite market continues to grow, both in established markets such as construction and the automotive industry as well as in new consumer goods markets which are creating many new innovative uses for these materials.

Pros

We use plant-based biocomposite materials mainly for their excellent mechanical performance, strength, stability, lightness and thermoforming capacities. Biocomposites are aesthetically pleasing and therefore create high-quality items.

They are just as stable and malleable as their petrochemical cousins. They are also light, which allows the final product to have thinner material and therefore weigh less. Biocomposites are also very good acoustic insulators.

In terms of their manufacture, the use and/or reuse of plant bases has a positive impact on both energy production costs and the financial costs to make such materials. Finally, these new-generation materials respect the environment, as they use both natural and local resources. Prioritising their use reduces the carbon footprint and toxicity of materials. At the end of their life cycle, these materials are fully biodegradable and/or recyclable.

Cons

Like with all new technologies or materials, there is still a lack of perspective and experience on their use, as they came about only very recently. Above all, we must make sure to use 100% biosourced composites, especially those that do not take from human food sources where possible. There are many promising materials, some of which are excellent alternatives to their petrochemical equivalents, while others are clearly on the wrong track.

We need to learn to accept small potential imperfections depending on the material chosen to make the item. We must also take its use into account and choose a material with appropriate characteristics (not all materials can be used for all purposes).

Finally, we absolutely have to pay attention to the origin of the material (where is it manufactured?) to make sure our environmental message remains consistent.

We would be happy to produce your next biocomposite item. Please do not hesitate to contact us to discuss your future project.

For an overview of our research into innovative materials, visit the Inovalab page.