ABS

Acrylonitrile butadiene styrene, or ABS, is a thermoplastic polymer belonging to the styrene polymer family. ABS undergoes a patented process called continuous mass polymerisation. This process uses no solvent or thinner, instead just heat or radiation. Once this process is completed, we get ABS.

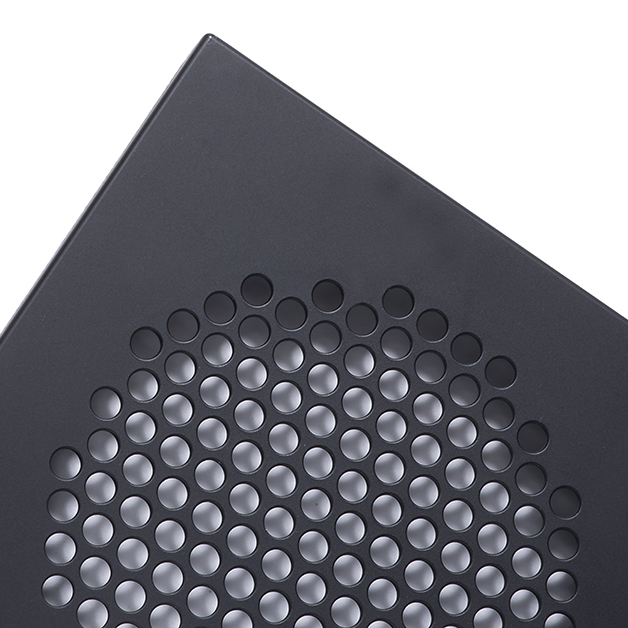

ABS is widely used in areas such as household appliances, telecommunications, computer equipment and toys. These include LEGO bricks, car bumpers and dashboards, remote controls, recycling bins, phone cases and 3D printer wires.

Pros

ABS is a resilient, impact-resistant plastic that is widely used in many industrial sectors. It has a low shrinkage coefficient and high dimensional stability and offers good resistance to both acids and bases.

ABS is light and has good abrasion resistance. ABS polymers are also resistant to many chemicals. ABS has a low melting point, making it easy to process with 3D desktop printers or injection moulding. It is a widely used material at an affordable price.

In terms of recycling, ABS can be recovered and mixed with virgin ABS to make new products.

Cons

ABS requires special maintenance to withstand time. It does not tolerate large variations in temperature: it degrades in the sun and during high temperatures in summer, and becomes brittle due to the cold in winter.

When exposed to UV rays, some ABS plastics containing bromine flame retardants tend to turn yellow. They react poorly when exposed to benzene, acetone and ethyl chloride. Unlike polystyrene, this plastic has poor electrical insulation properties.

We can make your next ABS products, but above all, we can try to offer you new recycled or non-fossil-based materials to limit your environmental impact. Please do not hesitate to contact us to discuss your future project.